Shock and Vibration

|

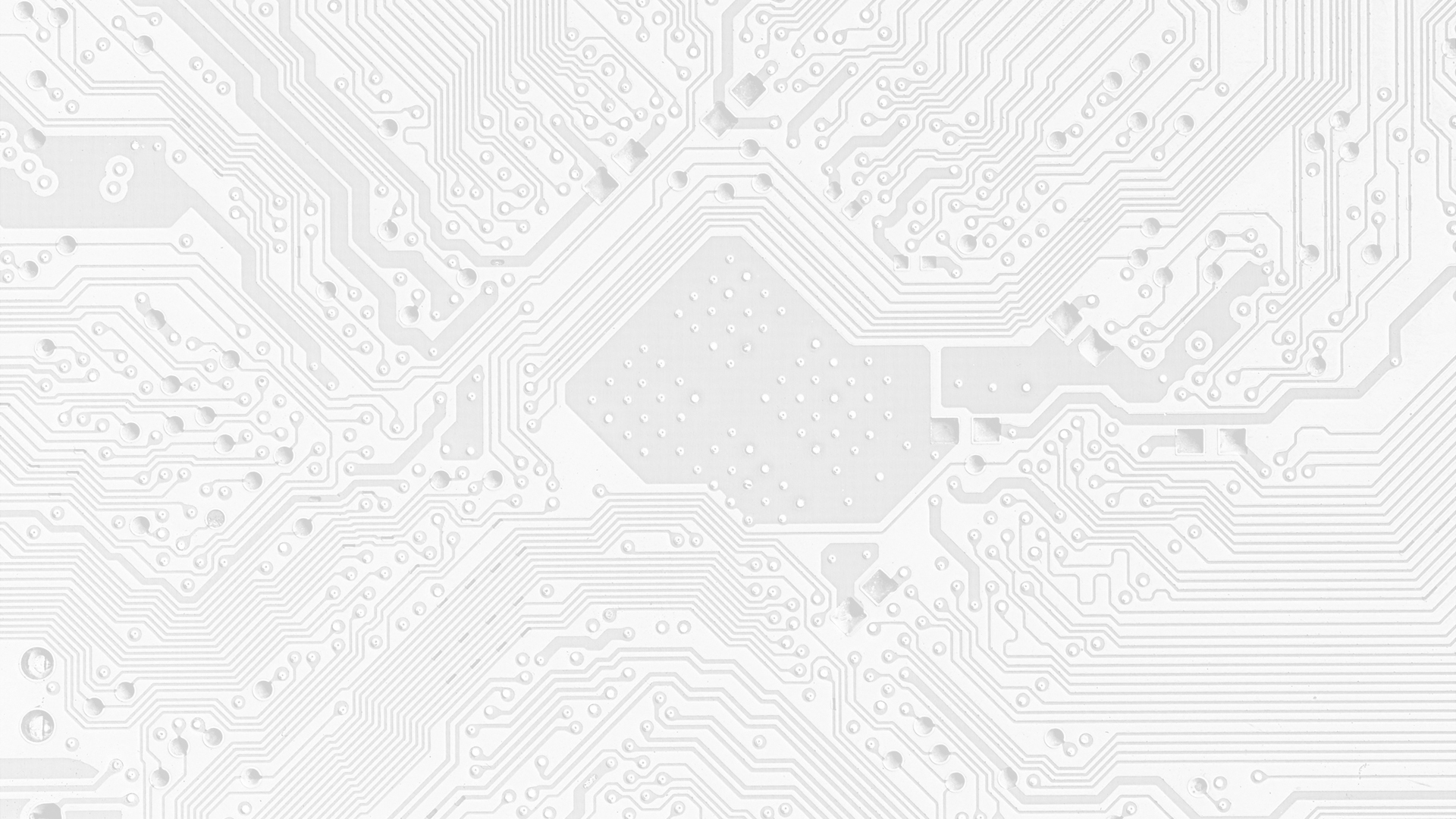

Electronic equipment can be subjected to many different forms of vibration over a wide range of frequencies and acceleration levels. All electronic equipment will be subjected to some type of vibration during its lifetime. If the vibration is not due to an active association with a machine or a moving vehicle, then it may be due to transportation of equipment from a manufacturer to a customer. Vibration is usually considered to be an undesirable condition because it can produce many different types of failures in electronic equipment. Mechanical vibrations can have different sources. In vehicles such as automobiles, trucks, and trains, most of the vibration is due to the rough surfaces over which these vehicles travel. In airplanes, missiles, and rockets, the vibration is due to jet and rocket engines and aerodynamic buffeting. Portable electronic devices such as pagers, palm-top organizers, and compactly designed cell phones are also vulnerable to damage from mechanical shock and vibration. With an indadvertent drop from a desk or bump against a wall, components can collide and render the device inoperable. Over a period of time, the post-shock ringing vibration can fatigue boards and connectors, which creates hard to spot electrical problems. Therefore, the testing of the electronic assemblies should include shock and vibration analysis. Portable products face the challenges of ever increasing functional density, shorter product cycles, and pressure to reduce costs. Increasing functional density has led to the explosive growth in chip scale package (CSP) usage. The expected life span for a portable product is short compared to many other product categories. However, portable products must survive multiple drops. The decreasing I/O pitch of CSPs, and the resulting smaller pads and solder joints, make the drop requirement more challenging. There are two approaches to improving drop reliability. The first approach involves altering the mechanical design of a product in order to minimize the shock and flexing of the printed circuit board that occurs when the product is dropped. The second approach involves utilizing underfills to mechanically reinforce the CSP solder joints. Consequently, the development of a robust mechanical design, capable of resisting multiple drops, is the preferred approach. Electronics inside of portable electronic products may be subjected from a few hundred Gs to thousands of Gs during an accidental drop from ear level (on average, approximately a 5 ft. drop height). The use of an experimental approach to test out every possible design variation, and identify the one that gives the maximum design margin, is often not feasible because of product development cycle time and cost constraints. There is a fundamental need for understanding and predicting the electronic failure mechanics in shock and drop impact. Figure 1 shows the drop orientation of printed circuit board assembly in vertical and horizontal (JEDEC) orientations. |

Figure 1: Drop Orientation of Printed Circuit Board (a) Vertical (b) Horizontal (JEDEC). |

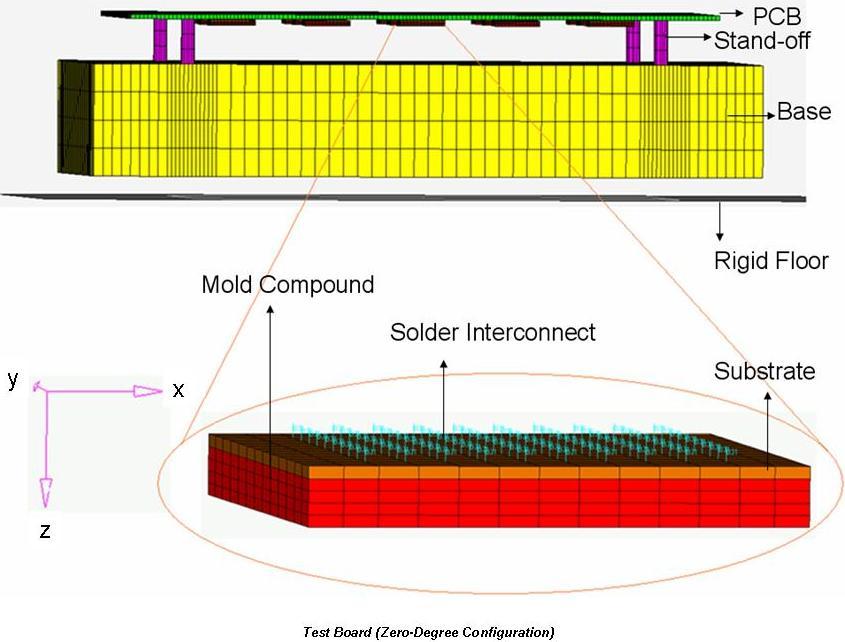

Figure 2: Explicit-Finite Element Model for Test Board in Zero-Degree JEDEC Drop Configuration. |

|

Transient dynamic deformation of the test boards is the wave propagation problem. The explicit finite element model of drop impact of the test board under zero-degree-JEDEC drop orientation is shown in Figure 2. The JEDEC specifications require that the PCB be mounted with packages facing downwards, and mounted on a rigid base with the help of four-corner standoffs. The peak acceleration for this test is 1500 Gs at 0.5 ms half-sine pulse. The transient drop event is modeled using the commercially available finite element code Abaqus ®. |

| Representative Recent Publications |

|

Lall, P., Pandurangan, A., Dornala, K., Suhling, J., Deep, J., Non-Perpendicular High-G Shock on Potted Fine Pitch Electronics Under Sustained High Temperature Aging, Proceedings of the 2021 IEEE 20th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, pp. 708-718, June 1-4, 2021. Lall, P., Kothari, N., Foley, J., Deep, J., Lowe, R., A Novel Micro-CT Based Finite Element Modeling Technique to Study Reliability of Densely Packed Fuze Assemblies, Proceedings of the ITHERM 2016, Las Vegas, Nevada, pp. 456- 464, May 31- June 3, 2016. Lall, P., Gupta, P., Angral, A., Anomaly Detection and Classification for PHM of Electronics Subjected to Shock and Vibration, IEEE Transactions On Components, Packaging And Manufacturing Technology, DOI: 10.1109/TCPMT.2012.2207460 , Vol. 2, No. 11, pp. 1902-1918, 2012. |