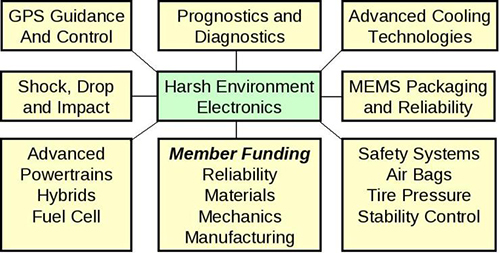

Research Thrusts

Components and Assemblies

In this research area, reliable component packaging technologies (BGA, CSP, 3D Packaging, QFN, etc.) are being developed for harsh environments such as automotive under-the-hood and aerospace applications and also for portable electronic products such as cell phones. The major goal is to develop fundamental knowledge on the interactions between component design and material selection on package reliability and thermal performance in harsh thermal cycling and vibration environments. Develop guidelines on the selection and use of components in harsh environments. Develop accelerated Test Data on Electronic Structures including but not limited to - metal backed boards, high Tg laminates subjected to extreme environments. Deliverables include crack propagation and damage models; thermal cycling reliability data; algorithms for prognostication; computational models for reliability and thermal performance; design guidelines and decision support tools; and models for shock, drop, and vibration.

Prognotics and Diagnostics

Leading indicators-of-failure are being developed for interrogation of material state significantly prior to appearance of any macro-indicators. The research focus is on determination of residual life of electronic systems via on-board sensing, damage-detection algorithms and data processing. Environments being studied include single, sequential, simultaneous thermo-mechanical, hygro-mechanical and dynamic loads.

Connectors and System-Level Interconnects

In this research area, the effects of vibration and environment on the performance of automotive and other harsh environment connectors are being evaluated. The primary goals are to examine connector interconnection options for next generation extreme environment applications and to establish the reliability and failure mechanisms. A basic understanding of the causes of fretting corrosion is being established, and then utilized to develop strategies for the accelerated testing of connectors. In addition, the growth of tin whiskers is being studied on connector pins with lead free plating finishes. The ongoing tin whisker research includes both fundamental studies on the origin of whisker growth and experimental test matrices to examine next generation connector designs. Deliverables from our Connector Reliability research include design guidelines, modeling tools, reliability data, and processing recommendations.

Flip Chip and Underfills

In this research area, materials and processes are being explored for flip chip on laminate, flip chip BGA packaging, CSP (redistributed die, Ultra-CSP, etc.) assemblies deployed in extreme thermal cycling environments. The primary objective is to develop a fundamental understanding of the reliability of flip chip applications in harsh environment applications and High End Microprocessor Packaging. Study next-generation materials (Nano-structured underfills, High-Reliability STABLCOR Substrates, Thermal Interface Materials, Chip-Level Interconnects). Project deliverables include design and material guidelines for flip chip packages used in the automotive thermal cycling environment; material properties and adhesion characteristics of underfill encapsulants; flip chip thermal cycling reliability data; assembly and manufacturing processing recommendations; and finite element and material models for application to future package designs.

Lead Free Soldering

In this research area, potential lead-free solder alloys and corresponding lead-free surface finishes (board and component) are being identified to replace eutectic 63Sn-37Pb solder in harsh environment applications. The primary goal is to develop a fundamental understanding of alternate solder alloys that will meet the high reliability, and high volume low cost manufacturing needs of the vehicle industry. Deliverables include recommended solder alloys; solderability (wetting) measurements; thermal cycling reliability data, stress-strain and creep results as a function of temperature, constitutive and solder fatigue models; and processing recommendations.