The Center for Advanced Vehicle and Extreme Environment Electronics (CAVE3) at Auburn University is dedicated to working with industry in developing and implementing new technologies for the packaging and manufacturing of electronics with special emphasis on the cost, harsh environment and reliability requirements of the vehicle industry.

Center personnel work directly with member companies to identify challenges and opportunities for new materials, processes, and approaches for the production of electronics. Member companies select the research projects, and semi-annual project reviews, visits, monthly updates, and frequent phone calls assist in the maintenance of close partnerships between industrial members and Center researchers. CAVE3 currently has 30 members teamed up with Auburn representing material, component, equipment and electronics assembly companies.

Announcements

Spring 2021

Lall serves as Panelist on Sustainability and Power at the 2021 FLEX Conference, February 22-26, 2021

Dr. Lall served as a panelist the 2021 FLEX Conference, speaking on subjects related to thin flexible power sources design and performance and reliability in wearable applications. The FLEX Conference focuses on flexible hybrid and printed electronic products, equipment, processes, and materials, emphasizing the latest technical breakthroughs, unique electronic applications, and business strategies.

Hamasha and Lall Serve on the SMTA Technical Committee for SMTAI 2020, November 1-4, 2020.

Drs. Hamasha and Lall served on the SMTA International Technical Advisory Committee to program the Harsh Environments and Advanced Packaging Tracks at SMTAI 2020.

CAVE3 Researchers Present Research Papers at the ASME InterPACK 2020 Virtual Conference

CAVE3 students presented papers and posters in virtual format at ASME InterPACK 2020, which was held from October 27-29, 2020. Topics included extreme environment electronics, material constitutive behavior, and additively printed electronics.

CAVE3 Researchers win Top Honors at the ASME InterPACK 2020 Virtual Conference

Two papers were recognized with the Outstanding Paper of Conference Award at the ASME InterPACK 2020 Virtual Conference:

1.) Reliability of Flexible Wearable Band with Printed Sensors for Vital Sign Acquisition, Lall, P., H. Jang, C. Hill, and L. Creel, in Proceedings of the ASME International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, ASME InterPACK, Paper IPACK2020-2644, pp. 1-8, October 27-29, 2020.

2.) Process Consistency in Additive Printed Multilayer Substrates With Offset-Vias Using Aerosol Jet Technology, Lall, P., K. Goyal, and S. Miller, in Proceedings of the ASME International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, ASME InterPACK, Paper IPACK2020-2680, pp. 1-11, October 27-29, 2020.

Lall Serves as Session Chair for Additively Printed Electronics at ASME InterPACK 2020

Dr. Lall served as a session chair for a panel on additively printed flexible electronics. The panel featured four of the mainstream technologies, including aerosol-jet printing, inkjet printing, direct write, and large-area screen printing. Represented companies included Optomec, nScrypt, SUSS MicroTec, and Komori. The process controls and opportunities were discussed. Dr. Lall, Ben Leever, and Janos Veres served as the track chairs of the Additive Printed Electronics Track at the conference. The track included a number of sessions focused on the manufacturing processes, performance, and reliability of FHE.

Lall Serves as Featured Speaker at SMTA Additive Electronics TechXchange 2020

Dr. Lall was a featured speaker at the SMTA Additive Electronics TechXchange on October 15, 2020. His speech focused on process development for additive printing of multilayer substrates.

CAVE3 Faculty to Research Lead-Free Defense Electronics as Part of Defense Electronics Consortium

Auburn University will soon help strengthen the economic and force posture of the United States' lead-free defense electronics industrial base through participation in the newly-launched Defence Electronics Consortium (DEC). The interdisciplinary project is a collaboration between faculty in Auburn's Industrial and Systems Engineering and Mechanical Engineering departments. From the former, Dr. Sa'd Hamasha will direct the research program. Participating faculty from the Department of Mechanical Engineering include Department Chair and Quina Professor, Dr. Jeffrey Suhling, and Graduate School Dean and Professor, Dr. George Flowers, as co-principal investigators. According to Hamasha, "The goal is to enable future new solders and electronics packaging technologies and processes for specific defense use cases."

Fall 2020

CAVE3 Graduate Research Assistants Win Best-Paper Awards at ITHERM 2020 Conference

Three CAVE3 Graduate Research Assistants received top awards at the ITHERM 2020 Virtual Conference, which was held from July 21-23, 2020.

Outstanding Paper of Conference Award: Lall, P., T. Thomas, and K. Blecker, RUL Estimations of SAC305 solder PCBs under different conditions of temperature and vibration loads, Proceedings of the 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, pp. 1340-1349, July 21-23, 2020.

Best Overall Poster Award: Mondal, D., A. Fahim, J. Suhling, P. Lall, Modeling Deformation Behavior of Multiple Grained SAC305 Solder Joints, Proceedings of the 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, pp. 1221-1229, July 21-23, 2020.

Outstanding Poster Award, Emerging Technologies and Fundamentals: Lall, P., V. Soni, and S. Miller, Effect of Dynamic Folding with Varying Fold Orientations and C-rates on Flexible Power Source Capacity Degradation, Proceedings of the 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, pp. 854-860, July 21-23, 2020.

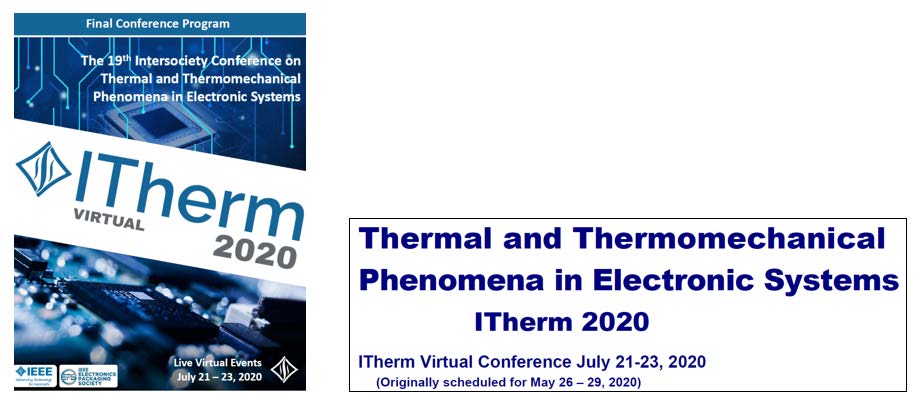

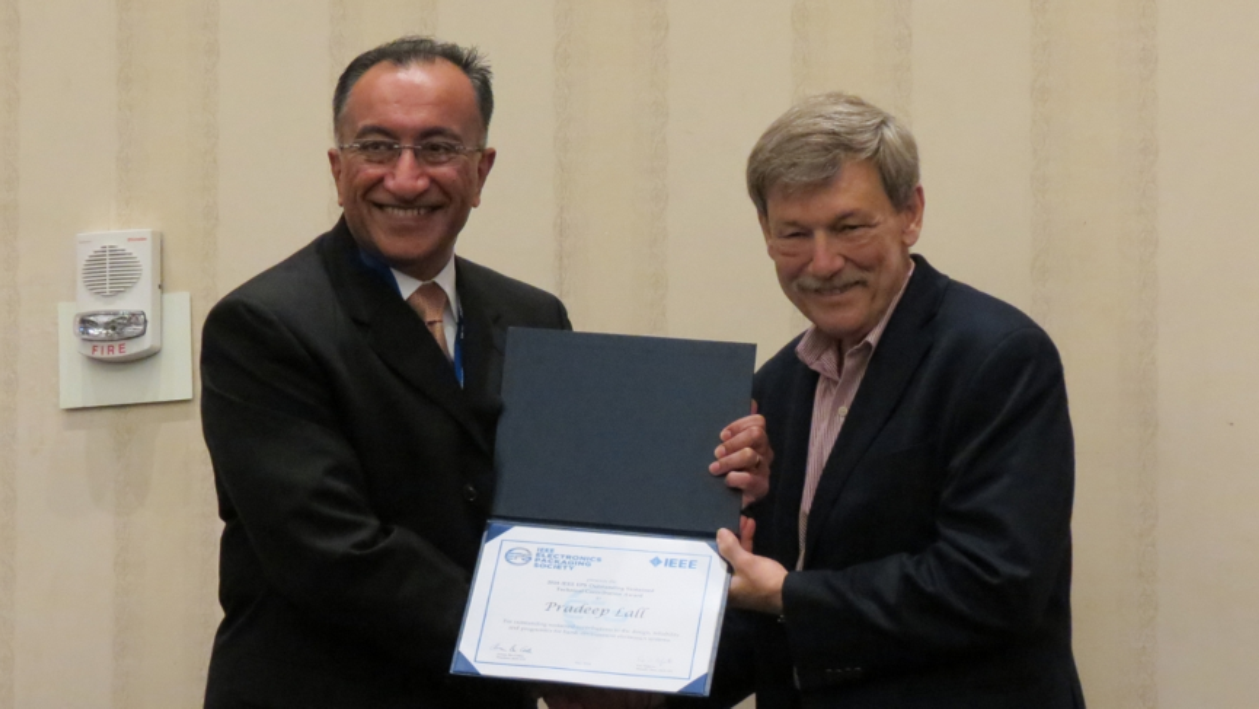

Lall honored with IEEE Biedenbach Outstanding Engineering Educator Award

Pradeep Lall, the John and Anne MacFarlane Endowed Distinguished Professor of mechanical engineering, is the recipient of the IEEE Region 3 Biedenbach Outstanding Engineering Educator Award for 2020, which recognizes those who have made outstanding contributions to the electrotechnology profession through teaching in industry, government or an institution of higher learning. Lall, director of the National Science Foundation Center for Advanced Vehicle and Extreme Environment Electronics (CAVE3), was recognized for his contributions to education in the field of additively printed electronics manufacturing and reliability for harsh environment operation.

"Dr. Lall is a world-renowned expert, researcher and teacher in the field of electronics", said Jeff Suhling, Quina Endowed Professor and chair of the Department of Mechanical Engineering. "I am delighted to see him recognized with the IEEE Biedenbach Award". Lall says that one of his professional motivations is to demystify certain aspects of additively printed electronics and harsh environment electronics.

Pradeep Lall, Macfarlane Endowed Distinguished Professor

"Through my publications and courses, I try to make the subject more accessible to a wider audience, from high schoolers to practicing engineers," said Lall, who has been the principal investigator on a number of research initiatives focused on those topics. "The topic of harsh environment electronics has implications in a number of industries including automotive, downhole and defense. The use of additive technologies provides pathways for faster time-to-market and productization of ideas and intellectual property."

A significant portion of Lall's research includes partnerships for workforce development. Accordingly, Lall has engaged high school teachers in sponsored research programs that expose students to additive electronics manufacturing at the K-12 level. He has engaged undergraduate students in Research Experiences for Undergraduate programs and generally advises a number of undergraduate students working on research projects on a regular basis.

In his role as director of CAVE3, Lall leads research projects in harsh environment electronics while interfacing with companies and government agencies that fund the center's research. He leads a sizable team of graduate students in working on a wide range of programs with significant implications in the electronics sector of the nation's growing additive manufacturing industry.

Lall was part of the founding proposal team for the NextFlex National Manufacturing Institute, which aims to renew and maintain the national focus of flexible electronics manufacturing; Auburn University is a tier-1 academic member of NextFlex. Lall also sits on the Technical Council and Governing Council of the NextFlex National Manufacturing Institute, as well as serves as the academic co-lead for the Asset and Situational Awareness Technical Working Group in NextFlex. He was named a NextFlex Fellow in 2019.

"Dr. Lall has created a world-class research program in additively printed-electronics manufacturing at Auburn University," said Christopher B. Roberts, dean of engineering. "This award adds to the recognition of the impact that he has made at the national level."

Augmentation of Additive Printed Flexible Electronics Capabilities at CAVE3

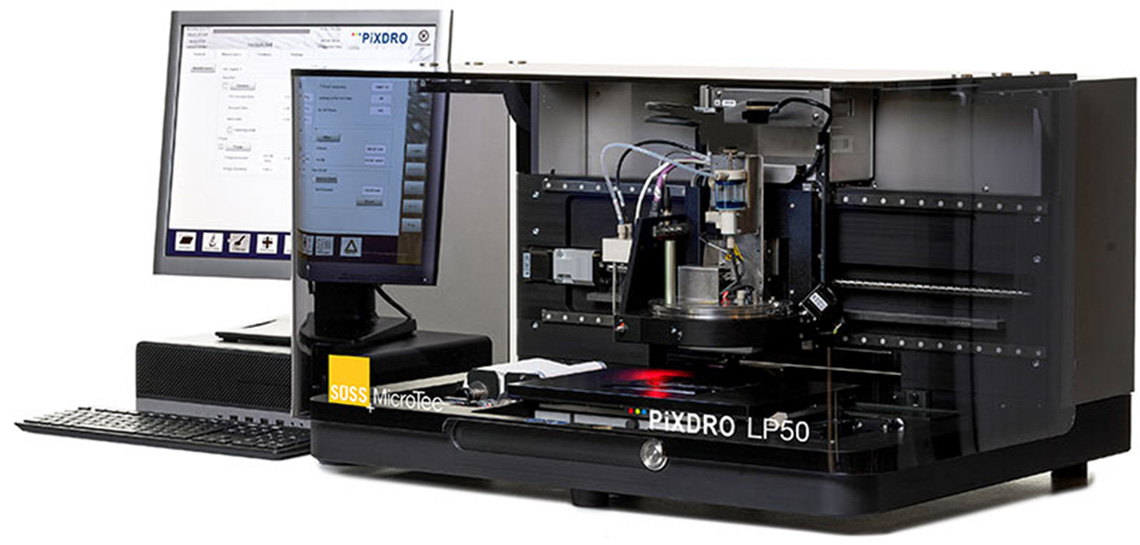

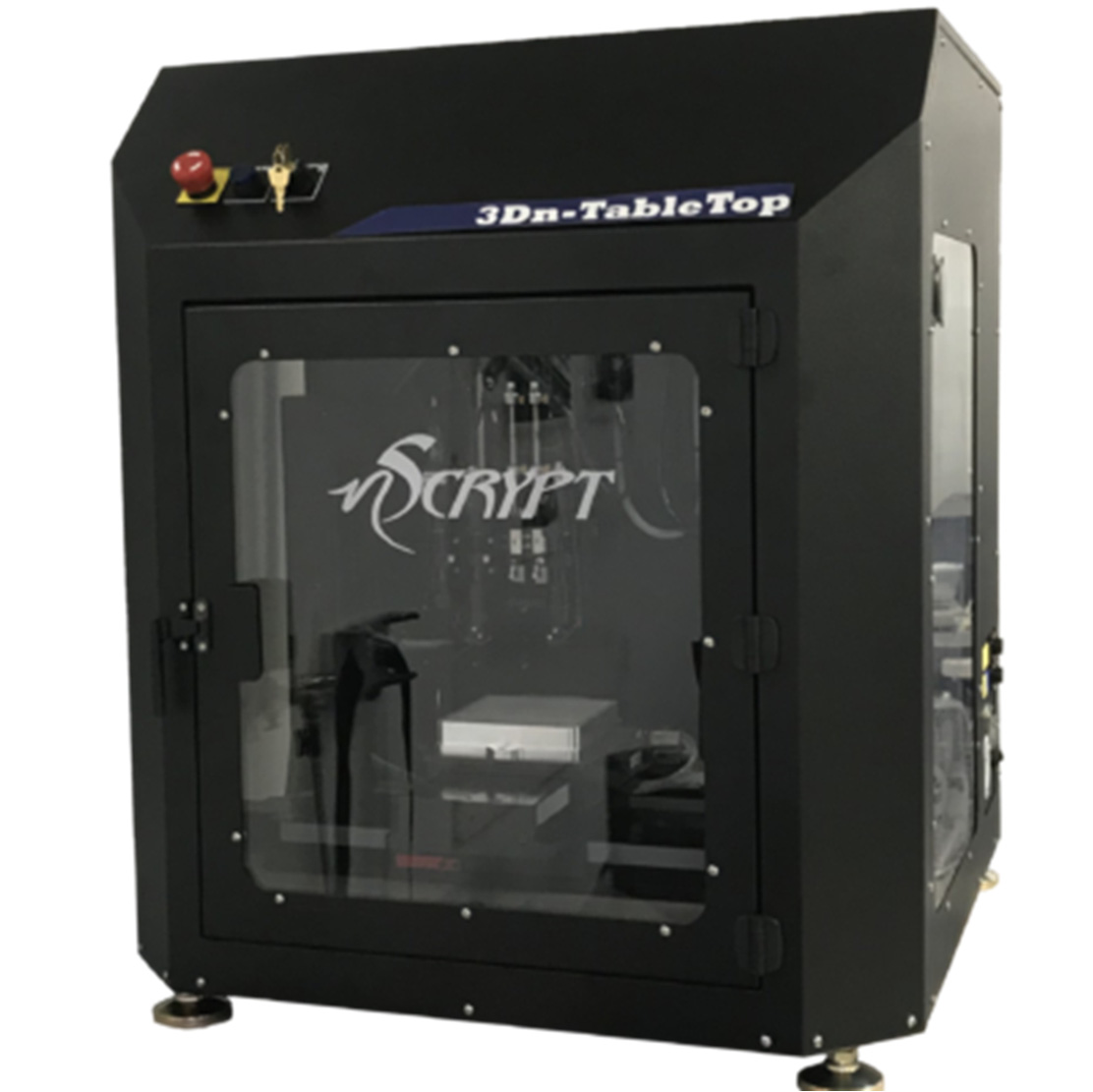

A number of key-pieces of equipment have been procured by the CAVE3 Electronics Research Center to augment the already formidable set of tools. Additional tools include (1) SUSS MicroTEC PixDro LP50 Inkjet Printer (2) nScrypt 3Dn-300 Direct Write Quad-Head Printer (3) Xenon X-1100 Photo-sintering System with Flatbed Capacity (4) Lamination Encapsulation for FHE.

SUSS MicroTEC PixDro LP50 Inkjet Printer

nScrypt 3Dn-300 Direct Write Quad-Head Printer

Xenon X-1100 Photosintering System

Lamination Encapsulation for FHE

Lall Serves as Track-Chair of the Additive Printed Flexible Electronics Track at ASME INTERPACK 2020

Professor Lall will serve as the track-chair of the Additive Printed Flexible Electronics Track at ASME INTERPACK 2020. Dr. Ben Leever, US-AFRL and Dr. Janos Veres, NextFlex are track co-chairs. The conference will be held in a virtual live format and is scheduled for October 27-29, 2020.

Spring 2020

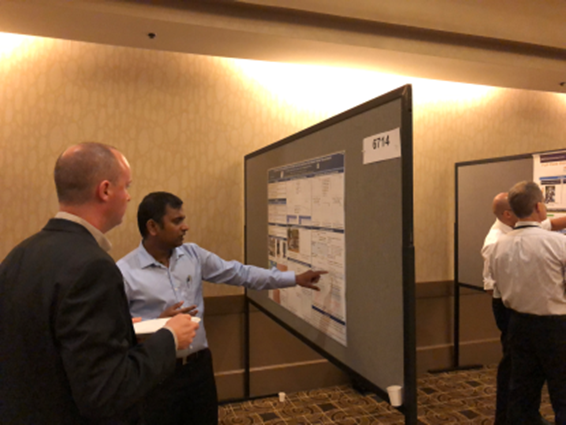

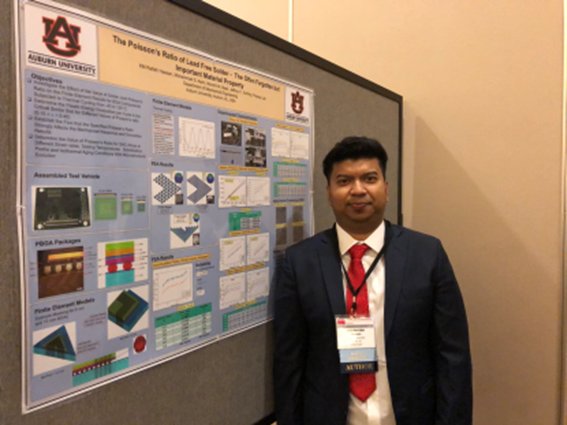

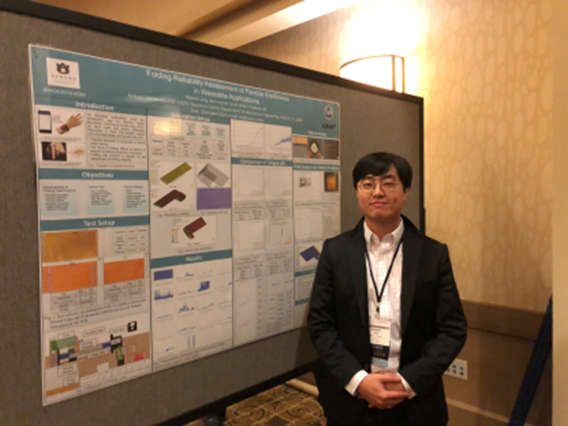

CAVE3 Researchers Present Research-Papers at the ASME INTERPACK 2019 Conference in Anaheim, CA

CAVE3 Students attended and presented at the ASME INTERPACK Conference in Anaheim, CA from October 7-9, 2019. Twenty papers were presented by CAVE3 researchers, and presentations included both oral and poster sessions. The papers presented touched on a number of cutting-edge topics in the general area on harsh environment electronics presenting break-through findings in modeling, reliability, testing and life-prediction of electronic systems. The CAVE3 team from Auburn University presented their research on additively printed flexible electronics manufacturing process development and test protocols. AU-CAVE3 has a full suite of tools for additively printed flexible electronics using aerosol-jet, screen printing, dispense-on-demand printing and ink-jet printing. In addition, CAVE3 has established itself as one of the leaders in the design and testing of flexible hybrid electronics.

Tony Thomas Vishal Mehta Kartik Goyal Ved Soni

Jinesh Narangaparambil Rafidh Hassan Hyesoo Jang Promod Chowdhury

Professor Lall served as a panelist for a panel on the topic of "Reliability in the Age of AI: Opportunities and Challenges". Other panelists included Mohak Shah from LG Electronics, Przemek Gromola from Bosch, and Anna Prakash from Intel. In addition, Professor Lall chaired the Session 4-3 on Flexible Electronics Packaging and Assembly.

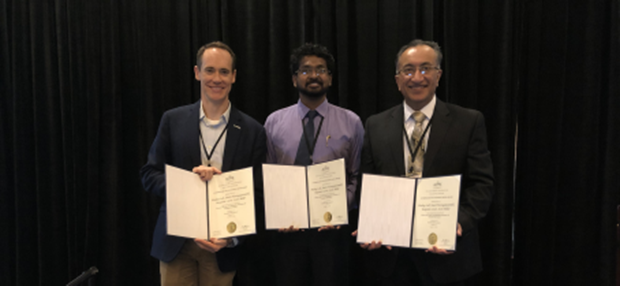

CAVE3 Researchers win Top-Honors at the ASME INTERPACK 2019 Conference in Anaheim, CA

The following was recognized as Outstanding-Paper of Conference Award at the ASME INTERPACK 2019

Lall, P., Narangaparambil, J., Leever, B., and Miller, S., Flexure and Twist Test Reliability Assurance of Flexible Electronics, ASME 2019 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems (ASME INTERPACK 2019), Anaheim, CA, pp. 1-10, October 7-9, 2019.

Left-to-Right: Ben Leever (US AFRL), Jinesh Nar-

Narangaparambil (AU), Pradeep Lall (AU) receiving

the 'Outstanding Paper Award' at ASME Inter-

PACK 2019 in Anaheim, CA.

Dr. Lall (center) with CAVE3 Ph.D. Students

(front row: left to right) Hyesoo Jang, Ved Soni,

Vishal Mehta, Jinesh Narangaparambil, Vikas

Yadav, Aathi Pandurangan, Tony Thomas

(back row: left to right), Kalyan Dornala,

and Kartik Goyal at InterPACK 2019

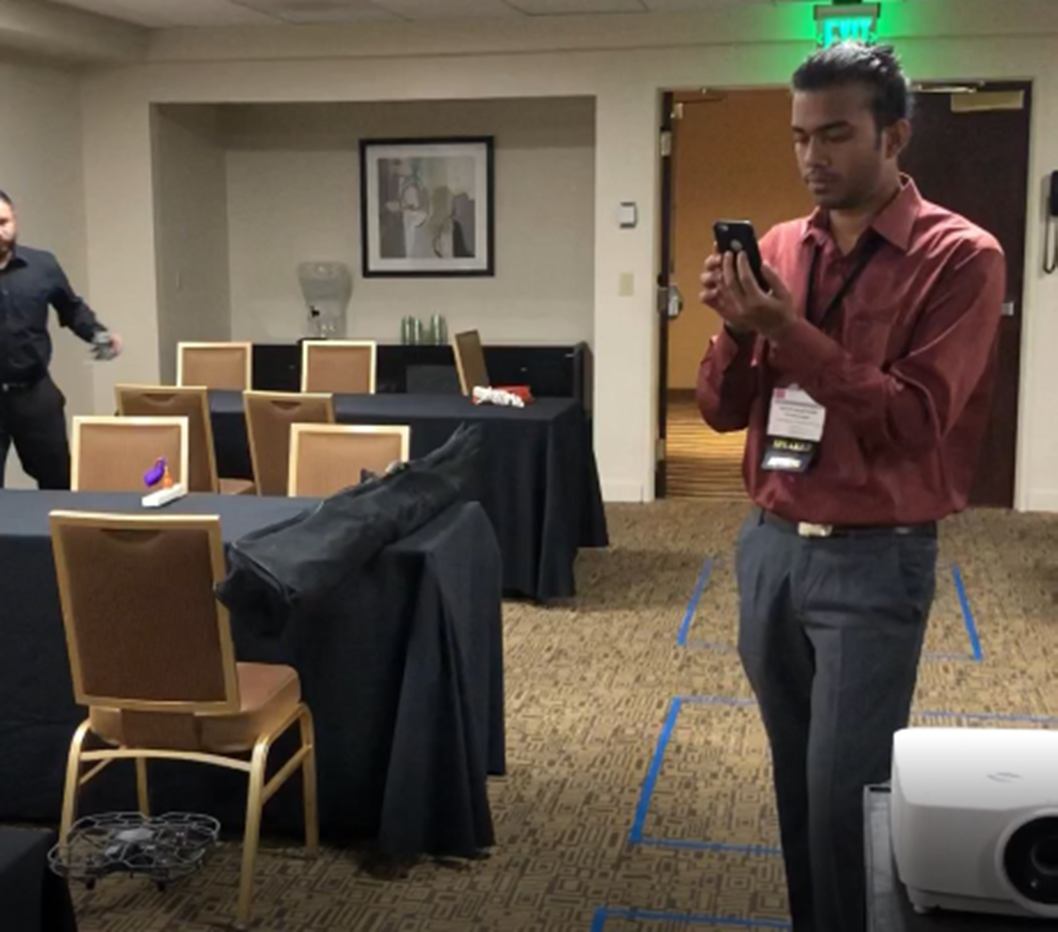

Aathi Pandurangan films a test flight of the

smartphone-operated drone at ASME Inter-

PACK 2019

CAVE3 Researchers Attend and Present at SMTAI 2019

Drs..... Lall and Hamasha chaired sessions and presented papers at SMTAI 2019 from September 22-26, 2019:

X-Ray Microcomputed Tomography Based FE-Models to Capture Realistic Manufacturing Variability in Cu-Al Wirebonds and Solder-Joints in QFNs, Lall, P., Kasturi, M., Kothari, N., and Locker, D., Proceedings of SMTAI, pp. 1-13, September 22-26, 2019

Effect of Cure Conditions on the Interface Properties and Reliability of Potted Electronics in 25,000g Mechanical Shock, Lall, P., Dornala, K., Lowe, R., Deep, J., Proceedings of SMTAI, pp. 1-10, September 22-26, 2019.

Thermal Cycling Reliability of Newly Developed Lead-Free Solders for Harsh Environments, Sa'd Hamasha, Proceedings of SMTAI, September 22-26, 2019.

Microstructure and Mechanical Properties of SAC-Bi Solder Alloys with Aging, Sa'd Hamasha, Proceedings of SMTAI, September 22-26, 2019.

Lall Receives MacFarlane Distinguished Professorship

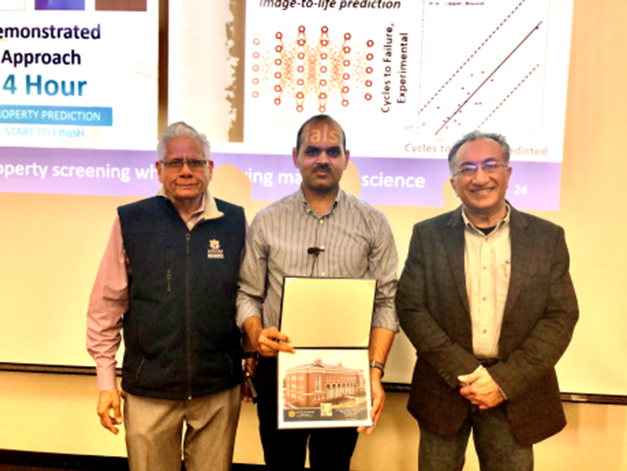

On October 23, 2019, Dr. Lall was awarded a prestigious 'Distinguished Professorship' in the Department of Mechanical Engineering by Auburn University Provost Bill Hardgrave and Samuel Ginn College of Engineering Associate Dean for Research Steven Taylor.

Dr. Lall (center) with Auburn University Provost Bill

Hardgrave (right) and College of Engineering Associate

Dean for Research Steven Taylor (left)

Dr. Hamasha Receives Prestigious IPC Teaching Award

On December 11, 2019, CAVE3 faculty member and Auburn University Industrial and Systems Engineering Professor Dr. Sa'd Hamasha received the 2019 Michael V. Carano Teacher Excellence Award from the IPC (the Association Connecting Electronics Industries). This award is the most prestigious award that IPC gives to recognized educators who enrich the lives of students interested in a career path in the electronics industry. There is only one awardee per year.

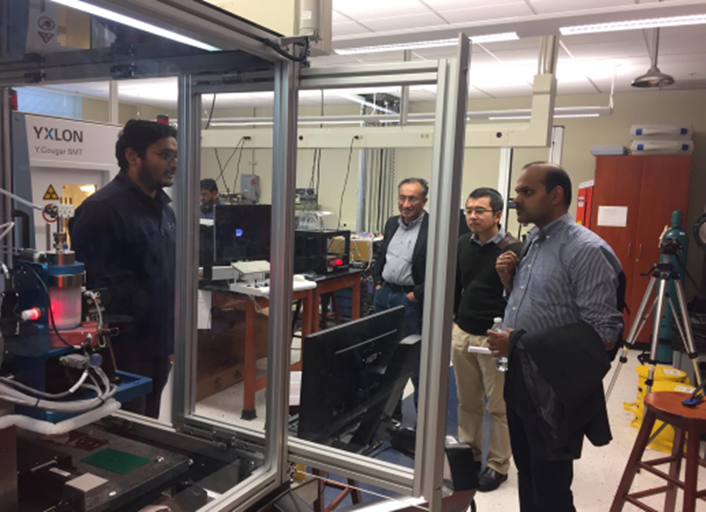

GE Research Visits Department of Mechanical Engineering and CAVE3

On October 25, 2019, the Department of Mechanical Engineering hosted a seminar entitled 'Advances in Additive Manufacturing at General Electric', during which Dr. Vipul Gupta discussed the current technological advances and research progress that he and his colleagues are making at GE Research. Dr. Gupta visited the CAVE3 Research Labs to view research in additive printed electronics. He has been leading efforts to combine physics with artificial intelligence machine learning to advance alloy design, AM processing, sensors and analytics, and post-production inspection; and transitioning these technical developments into real GE products.

Left-to-right: Kartik Goyal (AU), Pradeep Lall (AU),

Xiaoyuan Lou (AU), Vipal Gupta (GE)

Drs..... Pradeep Lall (right) and P.K. Raju (left) meet

with Dr. Vipul Gupta following the seminar

CAVE3 Ph.D. Student Wins Best Poster Award at Mechanical Engineering Conference

CAVE3 Doctoral Candidate Nakul Kothari won the 'Best Poster Award' at the Auburn University Department of Mechanical Engineering's 16th Annual Elements of Mechanical Engineering Conference, which occurred from September 30-October 1, 2019. His poster is entitled "Analysis of Progressive Damage in Fuze Electronics using Micro-Computed Tomography and Finite Element Models".

Fall 2018

Students from Auburn University Attend the 2018 ITherm and ECTC Conferences in San Diego, CA

CAVE 3 Researchers won top honors for their papers and presentations when they attended the 2018 ITherm and ECTC conferences in San Diego, CA from May 29-June 1, 2018. Overall, they presented 40+ papers in both the oral and poster sessions. A list of the technical papers is included in the technical publications section of the Fall 2018 newsletter.

Vikas Yadav Jinesh Narangaparambil Nakul Kothari Abdullah Fahim

Shantanu Deshpande Kartik Goyal Kalyan Dornala Mohd Aminul Hoque

CAVE 3 Researchers Win Top Honors at ITherm 2018 Conference in San Diego, CA

Professor Lall with Amrit Abrol Professor Lall (right) receiving the Outstanding Paper Award

at ITherm 2018 from Thomas Brunschwiler, General Chair (left)

Outstanding Paper Award, Mechanics and Reliability Track, Oral Session

Lall, P., Luo, Y., Nguyen, L., A Novel Numerical Metaphysics Framework for the Modeling of Cu-Al Wire Bond Corrosion under HAST Conditions, ITherm, San Diego, CA, U.S., pp. 1177-1184, May 29-June 1, 2018.

Outstanding Paper Award, Poster Session

Lall, P., Abrol, A., Leever, B., Marsh, J., Flexible Power-Source Survivability Assurance under Bending Loads and Operating Temperatures Representative of Stresses of Daily Motion, ITherm, San Diego, CA, U.S., pp. 1027-1035, May 29-June 1, 2018.

Best Paper Award, Poster Session

Fahim, A., Ahmed, S., Suhling, J., Lall, P., Mechanical Characterization of Intermetallic Compounds in SAC Solder Joints at Elevated Temperatures, ITherm, San Diego, CA, U.S., pp. 1081-1091, May 29-June 1, 2018.

Lall wins IEEE Outstanding Sustained Technical Contributions Award

Professor Lall (left) receiving the Outstanding Sustained

Technical Contributions Award from Avram Bar-Cohen,

President of IEEE Electronic Packaging Society,

at ECTC 2018 in San Diego, CA

Pradeep Lall, MacFarlane Endowed Professor in the Department of Mechanical Engineering at Auburn University, is the 2018 recipient of IEEE's Outstanding Sustained Technical Contributions Award for outstanding sustained contributions to the design, reliability, and prognostics for harsh environment electronics systems. The award recognized his seminal contributions to the field of harsh environment electronics. Lall is widely credited with the development of leading indicators of failure for prognostics health management of electronic systems to allow for early identification of faults that may impair system operation. He also is the author and co-author of over 500 journal and conference papers in the fields of electronics reliability, safety, energy efficiency, and survivability.

"This award is a recognition of Dr. Lall's international reputation and the impact of his contributions to state-of-the-art innovation", said Christopher B. Roberts, Dean of the Samuel Ginn College of Engineering at Auburn University. "His work has positioned Auburn Engineering to be a leader in harsh environment electronics."

"Electronics is pervasive in today's consumer products and many of the functions are safety critical", Lall said. "Take present day automobiles -- electronics enables much of the safety critical circuitry in present-day cars", he added. "Examples include lane-departure warning systems, collision avoidance systems, and park and drive assist systems. Given the level of criticality and need for continued reliable operation, it is important that problems be identified prior catastrophic failure. Many electronics reside under the hood of the automobile where temperatures and vibration loads are very high. Ensuring survivability for sustained operation of electronics is a continuing evolving challenge with the miniaturization of electronics."

Lall joined the Auburn University faculty in 2002 after a distinguished industry career at Motorola, where he worked on the development and manufacture of wireless products such as cellphones and two-way radios. He is also a fellow of IEEE. The honor was conferred at the IEEE Electronic Components and Technology Conference (ECTC), a premier international event attended by more than 1,700 individuals, during May 2018 in San Diego, CA. Lall received $3,000 and a certificate for his achievements. IEEE is the world's largest technical professional organization for the advancement of technology. He is also a member of the Technical Council and Governing Council of NextFlex, and is the Director of the NSF Center for Advanced Vehicle and Extreme Environment Electronics at Auburn University.

Lall was previously recognized by the National Science Foundation as the recipient of the Schwarzkopf Prize for Technology Innovation in 2016. He also is the recipient of The Alabama Academy of Science's Wright A. Gardener Award, the IEEE Exceptional Technical Achievement Award, the ASME-EPPD Applied Mechanics Award, SMTA's Member of Technical Distinction Award, Auburn University's Creative Research and Scholarship Award, the Samuel Ginn College of Engineering Senior Faculty Research Award, and 20 'Best Paper' awards at national and international conferences.

Where are they now?

CAVE 3 has a long history of making an impact in workforce development in the field of harsh environment electronics, so alumni have gone on to have successful careers. I want to highlight two former students who I met with at conferences earlier this year.

Rahul Vaidya graduated from Auburn University in 2010 with a M.S. Degree in Mechanical Engineering. Rahul's research was focused on the topic of prognostics health management. Presently, Rahul works for Oculus VR (which is part of Facebook) as a reliability engineer. Prior to joining Oculus, he worked for Amazon Lab126 and Cisco Systems. Rahul was a Graduate Research Assistant in CAVE 3 and advised by Professor Lall.

Thesis: Interrogation of System State of Lead-Free Electronics Subjected to Mixed Sequential Steady-State and Cyclic Thermal Environments (2010)

Chandan Bhat graduated from Auburn University in 2008 with a M.S. Degree in Mechanical Engineering. His research was focused on the topic of prognostics health management. Presently, Chandan works for Xilinx as a Semiconductor Packaging Engineer. Prior to joining Xilinx, he worked for Cree for over 9 years. Chandan was a Graduate Research Assistant in CAVE3 and advised by Professor Lall.

Thesis: Solder Joint Reliability & Prognostication of Lead-Free Electronics in Harsh Thermo-Mechanical Environments (2008)

Left to Right: Professor Lall with Left to Right: Chandan Bhat

Rahul Vaidya at the IRPS Conference with Professor Lall at the ECTC

in San Francisco, CA, March 13, 2018 Conference in San Diego, CA,

May 31, 2018

Spring 2018

Professor Lall Presents the AU Biometric Band at the NextFlex Innovation Day on September 20-21 , 2017

CAVE 3 had a booth at the NextFlex Innovation Day held in San Jose, CA on September 20-21, 2017. Professor Pradeep Lall presented the Biometric Band and LifeSaver App developed at Auburn University's CAVE3 Electronics Research Center. The biometric band is capable of acquiring vitals of the wearer and transmits them wirelessly to a paired smartphone. The band was designed, and fabricated, in the NSF-CAVE 3 Electronic Research Center labs.

The intended application for the technology product demonstrator (TPD) is for operators working on the inspection and maintenance of aircraft fuel tanks. The fuel tanks are small and confined spaces in the aircraft, which reside in the fuselage and inside the wings. Inspection and maintenance operations require the operators to climb inside the confined space of the fuel tanks. Oxygen levels in a confined space may become depleted due to oxidation or depletion by another gas. The typical concentration of oxygen in the environment is 20.9 percent. When oxygen levels drop to the range of 19.5 percent to 12 percent, judgment is impaired, and personnel may experience an increased pulse rate and fatigue. If levels drop from 12% to 6%, fatigue will worsen and nausea and vomiting will occur. A dual-use aspect of the technology may include the following applications -- (1) monitoring the vitals of workers in high-heat environments to determine when workers need to come out of the heat before the effects of heat stress become a physical risk factor (2) monitoring of a lone worker in a hazardous environment.

The band has been designed in wear-and-forget format with multiple bio-medical sensors, including GPS, pulse-ox, pulse-rate, and electromyography sensor integrated with a microcontroller and Bluetooth communications link on a flexible high-density substrate. The smartphone app has been designed with the required logic processing the vital signals of the operator with capability of autonomous decision-making for contacting emergency services with the location of the operator if the operator's well-being has deteriorated. The approach involved the design of flexible substrate for the assembly and integration of sensors with a microcontroller for the acquisition of signals and a Bluetooth module for the transmission of vital data to the paired smartphone. The multi-sensor bio-medical band will be worn by the operator working in a confined space. The band will have multiple sensors, including GPS, pulse-ox, pulse-rate, and electromyography sensor for measurement of the loss of blood oxygenation resulting from depletion of oxygen in the environment in the fuel tank, abrupt changes in the pulse rate resulting from anxiety or claustrophobia, loss of consciousness, myocardial infraction, stroke, bradycardia or aneurysm.

Additional sensors can be added if needed to address a broader range of medical conditions. The raw data from the sensors is gathered by the embedded microcontroller on the wearable band through the GPIO and transmitted via the Bluetooth sensor on the USART port of the microcontroller to the paired smartphone. The LifeSaver App installed on the smartphone receives the transmitted data via the Bluetooth module and processes the data while checking for imminent danger to the operator. If the status is okay, the app continues to monitor silently. However, if the operator is in imminent danger or in need of medical attention, the app autonomously contacts emergency medical services with the GPS location of the operator and details on the operator's condition. Emergency medical personnel can be dispatched to the location of the operator immediately without any action needed on the part of the operator.

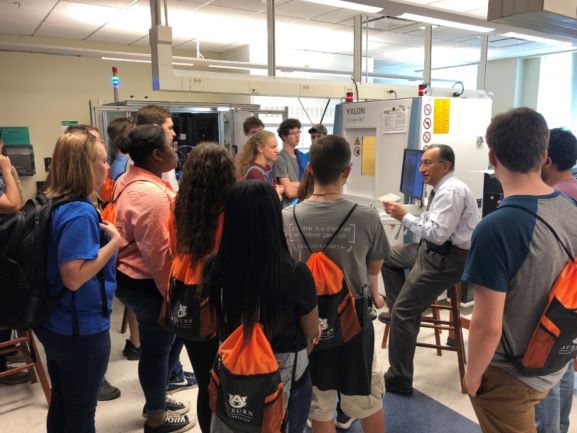

Auburn High and Junior High School students visit Flexible Additive Manufacturing Laboratory on E-Day

On February 23, 2018, we had the pleasure of hosting Auburn High School and Auburn Junior High School on E-Day. Students considering a career in engineering joined us to get a sense of the look and feel of the excitement of studying engineering at Auburn University. E-Day is a chance to learn about the research programs, laboratory facilities, and research opportunities offered in the College of Engineering. Seventh through twelfth graders had an opportunity to chat one-on-one with students and faculty and experience the interactive exhibits, including the new additive flexible electronics laboratory with capabilities of the vertically integrated manufacturing activities from design, fabrication, assembly, and tests of flexible electronics. The students also had a chance to see additive technology in action by through printing electronic circuits and sensors on non-planar and flexible surfaces. In addition, they had a chance to view methods used to study the reliability of the assembled structures in operational environments.

Professor Lall teaches Short-Course on Flexible Device Integration and Packaging at the 2018 FLEX Conference

Professor Lall co-taught a course on Flexible Device Integration and Packaging at the 2018 FLEX Conference with Doug Hackler (President and CEO of American Semiconductor) and Kurt Christensen (Senior Research Scientist at Optomec). The course, which was well attended, covered a number of topic, including the manufacturing processes for the fabrication of printed electronics, die-thinning processes, assembly processes needed for the production of ultra-thin chips on low temperature substrates, and the interconnection materials and technologies for first- and second-level interconnects. In addition, Professor Lall also presented two papers and spoke at the High Performance Flexible Printed Electronics Special Session:

Lall, P., Hackler, D., Christensen, K., Short-Course: Flexible Device Integration and Packaging, 2018 FLEX Conference, Monterey, CA, February 12-15, 2018.

Lall, P., Zhang, H., Lall, R., Development of Flexible Biometric Sensor Band with LifeSaver App, Session-7: Health Monitoring Systems, 2018 FLEX Conference, Monterey, CA, February 12-15, 2018.

Lall, P., Narangaparambil, J., Abrol, A., Test Protocols for Flexible Substrates in Wearable Applications, Session-14: Standards and Reliability, 2018 FLEX Conference, Monterey, CA, February 12-15, 2018.

Lall, P., High Performance Flexible Printed Circuits, NextFlex Special Session: High Performance Flexible Systems Roadmapping and Strategy, 8:00 am-11:00 am, February 16, 2018, held concurrently with the 2018 FLEX Conference, Monterey, CA, February 12-15, 2018.

Shantanu Deshpande Wins ASME 2017 Electronic and Photonic Packaging Division Student Member of the Year Award

Shantanu Deshpande, doctoral candidate in Mechanical Engineering, won the American Society of Mechanical Engineers' 2017 Electronic and Photonic Packaging Division Student of the Year Award. The Award recognizes a current student who has excelled in research, and has shown promise to be a strong contributor in the field of electronic and photonic packaging. Only one student is selected every year for this national award. After earning his bachelor's degree in Mechanical Engineering from Pune University, Deshpande came to Auburn University for his doctoral studies in 2012. He is working on reliability of coppor wirebonding in harsh environments in the Center for Advanced Vehicle and Extreme Environment Electronics under the direction of Pradeep Lall, the John and Anne MacFarlane Professor of Mechanical Engineering.